Senior Aerospace SSP turns innovative designs into functional systems

At Senior Aerospace SSP, there is no barrier between an innovative design and its production. Our engineering systems work directly with our manufacturing systems. Using SixSigma principles and guided by our SixSigma manufacturing “black belts” on our shop floor, we move rapidly from design through forming, fabricating, test and production. We take a systems approach to manufacture with an MRP system, manufacturing cells, Just-In-Time processes, HOC metrics boards, Kaizen events and Kanban to keep our cells supplied in a timely manner. We handle the entire logistics necessary for the efficient and cost-effective manufacturing of advanced ducting systems – including keeping appropriate levels of safety stock.

We have a dedicated High Volume Campus to support production ramp-ups in customer programs to avoid lines stopping in aircraft production. We have dedicated teams supporting our high volume campus to ensure that the quality of the parts are not being compromised and that customer demands are being met.

Our background is in forming and fabricating with no “off-the-shelf” systems. Each system and all its components are customs made for each customer program. We bend our own tubes, using the latest in multiple bend automatic equipment, as well as, manual techniques. We design and build our own tools, joints, and connections to support customer systems.

We are committed to manufacturing that is lean and green, and we can take each job all the way to kitted assembly for our customers. 90% of all the work done on any program is done in-house – giving SSP unprecedented control over the process from start to finish.

Manufacturing Capabilities

Support Capabilities in Manufacturing are:

- Computer-aided manufacturing using SolidWorks and Mastercam

- Tool Design

- Tool Fabrication

Component Fabrication Abilities Include:

- Hot and Cold Forming

- Punching and Shear

- Water Jet Cutting and Trimming

- Laser Trim

- Foundry

- Drop Hammer

- Spin Forming

- Tube Bending

- Traditional Machining

- CNC Machining

Assembly and NDT Capabilities:

- Bellows Forming (Hydro-Mechanical and Mechanical)

- Hand Assembly and fit-up

- Tig, Plasma, and Chamber Welding

- Semi-Automated Circumferential Welding

- Cleaning

- Heat Treating

- Insulating

- Acceptance, Pressure, and Leakage Testing

- Dye Penetrant Inspection

- Real Time, Conventional, and digital X-Ray

- Laser Tracker and Faro Arm Dimensional Inspection

Unique Manufacturing Solutions

Materials for unique solutions:

- Inconel

- Stainless steel

- Titanium

- Hastelloy

- Aluminum

Innovative materials for unique solutions:

- Composites

Innovative manufacturing solutions:

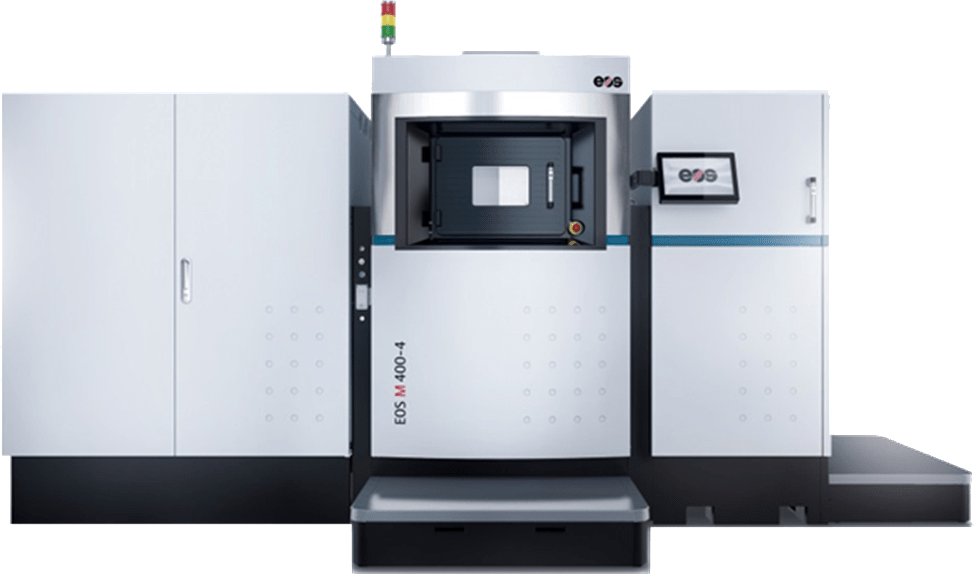

- Additive manufacturing